Our Design Approach

The firm has an extensive background with and knowledge of PEMB projects. Our low overhead results in lower design fees that can make the overall design-build bid more competitive.

During the design phase:

1) We use custom designed spreadsheets (1 span and 2 span PEMBs) that automatically calculate the metal building column reactions. This allows the design of the foundation system to be completed without waiting for the anchor bolt plan and column reaction package from the PEMB manufacturer.

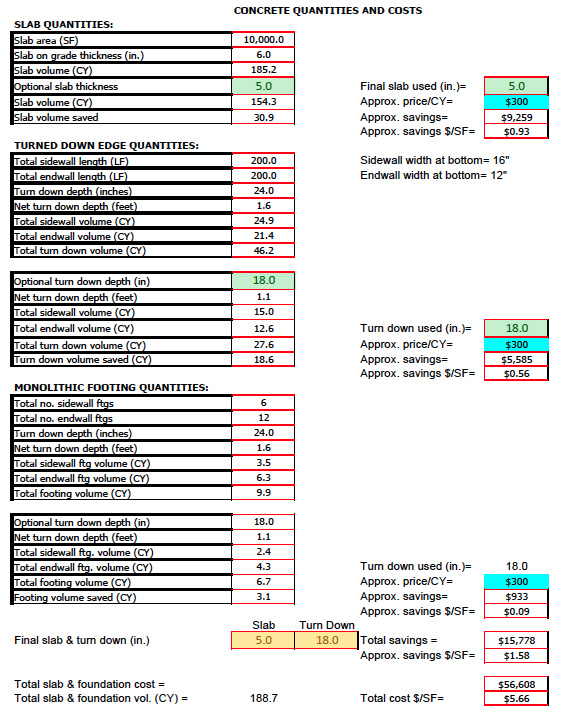

2) Using these custom designed spreadsheets for monolithic slab/foundation systems, we can optimize the concrete slab, footing and turned down slab edge costs. The spreadsheets automatically calculate the column footing sizes, turned down slab edge reinforcing, hair pin bar sizes, etc. Concrete quantities are automatically calculated and a budget concrete system cost for the intended system is determined. An optimization module allows the slab depth, footing sizes and turned down slab edge depth to be changed and the cost savings are automatically determined. For instance, for a 10,000 SF PEMB, reducing the slab from 6” to 5” can save almost 31 CY of concrete, which amounts to $7,400 at $240/CY. This is very important tool in a competitive bid situation.

3) We will promptly return calls, respond to emails and respond to design related changes.

4) We will work overtime to meet your design deadline. Our final drawings are electronically signed and sealed, sent via email. The intent is to complete our design and deliver the construction document package in a matter of days, not weeks.

5) PEMBs frequently involve non metal perimeter walls, such as EIFS/metal studs, masonry, tilt up concrete, etc. All non-PEMB wall systems are detailed on our drawings and coordinated with the PEMB system (how these walls are braced) via full height wall sections. Our construction documents provide shop drawing level of detail for all perimeter metal stud wall systems. The metal stud subcontractors have a clear set of documents to price from and build by. No design responsibility is delegated to the metal stud subcontractor.

6) All drawings are produced by Dave Williams, a licensed structural engineer, not by Computer Aided Design and Drawing (CADD) technicians. Eliminating the CADD ‘middle man’ expedites the design process.

|

Non-metal perimeter walls are completely detailed

Foundation System Optimization

|